Preface

Shanghai Muxiang Environmental High-Tech Co., Ltd. established in 2006, is a High-Tech Enterprise focusing on automation machinery and equipment based on China and facing the world. The company integrates innovation, manufacturing, sales, and service. It is a leading automation equipment manufacturer in China. Our company’s main management comes from the executives of listed companies with rich management experience. The R&D team is composed of engineers with more than ten years’ experience in equipment R&D and manufacturing. By the industry’s leading innovative R&D capabilities and more than ten years’ experience in serving nearly 1,000 high-end customers, we have the leading R&D technology in China. As many as 50 invention patents are owned by the company, and the product’s high praise rate is over 95%. Our company customized the following scheme for your company.

System Description:Include spiral conveyor and telescopic conveyor。

Technological process : Manually put the material on the spiral conveyor, Materials spiral down from the third floor to the first floor and enter the telescopic machine。

1.Basic design data

1.1Basic information

| Item Content | Basic Data | Ramark |

| Installation site | ||

| temperature | -5ºC — 45ºC | |

| Humidity | 5%~95%(No condensation) | |

| Noise | ≤75db | |

| Working Days | 7 days per week | |

| Working Hours | 16hours per day; | |

| Working voltage | 3-phase 380 VAC ±10%,50HZ±1HZ | The ground wire and zero wire shall be strictly |

|

separated,and the grounding resistance value shall be no more than 4 Ω |

||||||||

| Protection requirements |

IP55 for motor, IP65 for field instrument and sensor, IP54 for control cabinet and operation panel; |

|||||||

|

Transported products |

Wheat flour 1200(L)*700(W) | PP | woven | bag | , | |||

|

Weight of product |

MAX. 70kg | |||||||

|

Transportation mode |

Manual feeding,10 bat per minute。 | |||||||

1.2 Equipment matching requirements

Space demand

Floor opening size: 2800 * 2800

● Power supply requirements

Total power supply:380VAC±10%,50Hz±1Hz,three-phase five wire system;

Auxiliary power supply:220VAC±10%,50Hz±1Hz,single-phase two-wire system;

● Operating environment requirements

Indoor environment temperature:-5℃– 45 ℃

Indoor humidity:5%–95%,no condensation;

● Public engineering requirements

The screw machine is fixed by chemical anchor bolt M12 + top diagonal rod, which is fixed at the opening of corridor building.。

● Grounding requirements

In order to prevent the dangerous high voltage of electrical equipment in case of insulation damage or aging, the metal shell of electrical equipment which is not electrified under normal conditions should be grounded.

Most of the cables and wires in the system are laid inside or on the equipment, and the rest should be laid in the cable tray.

Grounding shall be carried out in the way of Muxiang

2. Scope of supply

2.1 Scope of supply 1.Spiral conveyor:

1.The material is made of 304 stainless steel plate.

2.The width of the spiral slide is 1000 mm.

3.The pitch of spiral slide is 3000mm.

4.The difference between the inlet and outlet of spiral slide is 5800 mm

5.The height of spiral slide entrance from the third floor is 800mm

6.The height of the spiral slide exit from the ground floor is 1000mm

7.The inlet and outlet of the spiral slide are arranged 180 degrees

8.The running direction of the material on the screw is clockwise.

9.The outlet of the spiral slide way is 1000 mm above the ground, and a telescopic belt conveyor is connected at the bottom.

10.The spiral slide is fastened by flange butting screw, which is convenient for installation. It is suitable for modular installation and splicing in small space.

11.The overall load of the slide is 1.5 tons.

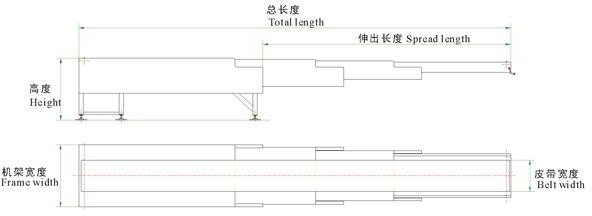

2.Telescopic conveyor:

Four sections:

Technical parameter selection table

| Model(Optional) |

Length |

MAX Length |

Total length |

Belt width (Optional) |

| MX-SSJ44-6/8 |

4000 |

7000 |

11000 |

600/800 |

| MX-SSJ45-6/8 |

5000 |

10000 |

15000 |

600/800 |

| MX-SSJ46-6/8 |

6000 |

12600 |

18600 |

800 |

| According to the requirements, we recommend the selection parameters marked in red | ||||

| MX-SSJ47-6/8 |

7000 |

15000 |

22000 |

600/800 |

| MX-SSJ47.5-6/8 |

7500 |

16000 |

23500 |

600/800 |

| MX-SSJ48-6/8 |

8000 |

17000 |

25000 |

600/800 |

Description of technical parameters:

1. Transported products

1.1 Product Name: box or bag product

1.2 Product size: (length x width x height) provided by customers

1.3 Weight: 70kg / piece.

1.4 Conveying time: 10 pieces / min.

2. Basic requirements of belt telescopic conveyor

2.1 standard 4 sections, 6 meters of body, 12 meters of extension, 18 meters in total.

2.2 Belt width 800mm.

2.3 telescopic machine height 900 mm.

3. Control and operation

3.1 Main power supply: 380V, 3Ph, 50Hz

3.2 Main power connection: independent power supply provided by customers

3.3 Control voltage: 24dc

3.4 Emergency stop: 2 in total, 1 main shell and 1 at the front end

3.5 Belt speed: 20-45m / min

3.6 Operation direction: forward / reverse

3.7 Power 2.2kW;

3.8 Belt drive: the reduction motor drives the roller through the sprocket chain.

3.9 Stretching speed: 11m / min;

3.10 Power 0.75kw;

3.11 Extension control: press the front button of the machine;

3.12 Retraction control: press the front button of the machine;

3.13 Emergency retraction: front bumper switch;

3.14 Light: 2 lights at the front end

3.15 Product sensing: installed in the front end

3.16 Control panel: installed at the front end of the main frame

4. Working conditions of equipment and facilities

4.1 Power supply: three phase five wire system;

4.2 Voltage: 380V ± 10%;Frequency: 50 Hz ± 2%;

4.4 Ambient temperature: summer ≤ 45 ℃, winter ≥ – 30 ℃;

4.5 Environmental humidity: relative humidity ≤ 79%;

5. Equipment safety and protection

5.1 The design of equipment and facilities shall comply with the latest international safety protection standards;

5.2 The equipment and facilities shall be equipped with perfect protective devices;

5.3 Separate protection for moving parts and oil, water, gas, wires, cables, etc

5.4 Noise of equipment and facilities in operation ≤ 80dB (a);

5.5 The equipment and facilities shall be equipped with emergency stop button or switch when necessary, which shall be installed at the position convenient for operation with bright color;

5.6 The color of fence and lighting device is warning color or warning color;

5.7 Safety colors such as safety indication and safety signal conform to national standard iso3864;

6. Surface treatment of equipment and facilities

6.1 Black metal profiles and their weldments, sheet metal structures and their weldments on the surface of equipment and facilities shall be treated with plastic spraying;

6.2 The appearance color of the equipment and facilities shall be treated in strict accordance

with the color card provided in the contract, and the different colors required for the modeling design shall be approved by Party A;

6.3 The surface of transmission parts shall be blackened or galvanized;

6.4 The purchased standard parts shall be subject to the primary color; (or purchased according to the executable scheme proposed by Party A)

6.5 The color of fence and protective device is warning color or warning color; or the color proposed by Party A;

7. Equipment design principle

7.1 The conveyor has beautiful appearance, compact structure, easy operation and maintenance, and meets the requirements of ergonomics;

7.2 The transmission structure is reasonable, the operation is stable and the action is reliable;

7.3 The original electrical appliances shall be designed and selected in strict accordance with the contract to ensure the high stability, reliability and safety of the whole control system;

7.4 The convenience of transportation and installation shall be considered as far as possible in the design of equipment and facilities;

7.5 Guarantee to provide cost-effective production equipment on the basis of meeting production process, output, management and maintenance;

8. Electrical control

8.1 motor selection

8.1.1 The rated power of motor meets the load requirements, and the power of motor, reducer and frequency converter matches the performance;

8.1.2 according to the environmental conditions of Party A, select the appropriate ventilation mode, structural form and protection level;

8.1.3 The margin coefficient of three-phase motor is 1.5-2.0, and the temperature rise during long-term operation shall not exceed 65 ℃ (Grade E) and 70 ℃ (Grade B);

8.2 selection and installation of electrical components

8.2.1 The circuit has over-current, phase loss, overload and other protection functions. The switch capacity should be selected properly and the overload capacity should be enough;

8.2.2 The original electrical appliances shall be arranged in order with clear line marks. The original electrical appliances and terminals shall be connected by cold pressing with lugs, and the wiring shall be firm without looseness, breakage or leakage;

8.2.3 Plastic trunking is used in the control box, and the wire number, control panel and label are clean and clear.

8.2.4 The installation of electrical appliances shall comply with the installation technical specifications, with reliable grounding device, grounding resistance ≤ 4 Ω, and insulation resistance of electrical system to ground ≥ 50m Ω;

8.2.5 The control line from the control box to the trunking section shall be wired with cable and metal hose;

9. Name, brand and origin of main materials of equipment

| NO. | Name | Function and purpose | Brand | Remarks |

| 1 | Belt motor | drive | Nord | power 2.2kw |

| 2 | Telescopic motor | drive | Nord | power 0.75kw |

| 3 | chain | drive | ZhengHe | ZhengHe |

| 4 | Wires and cables | control | QiFan | |

| 5 | Travel switch | Position control | OMRON | |

| 6 | 24 V power supply | Product control | Mingwei | |

| 7 | Relay contactor control | control | Schneider | |

| 8 | button switch | control | Schneider | |

| 9 | Deep groove ball bearing | transmission | NSK | |

| 10 | belt conveyor | transportation | Amara | 3mmPVK |

| 11 | inverter | transportation | Delta Taiwan | |

| 12 | Plastic spraying | surface treatment | DuPont | |

| 13 | PLC | Delta Taiwan | ||

| 14 | inverter | adjust speed | Delta Taiwan |

★The core tenet of Muxiang company is to manufacture products higher than customers’ expectation★

Post time: Mar-17-2021